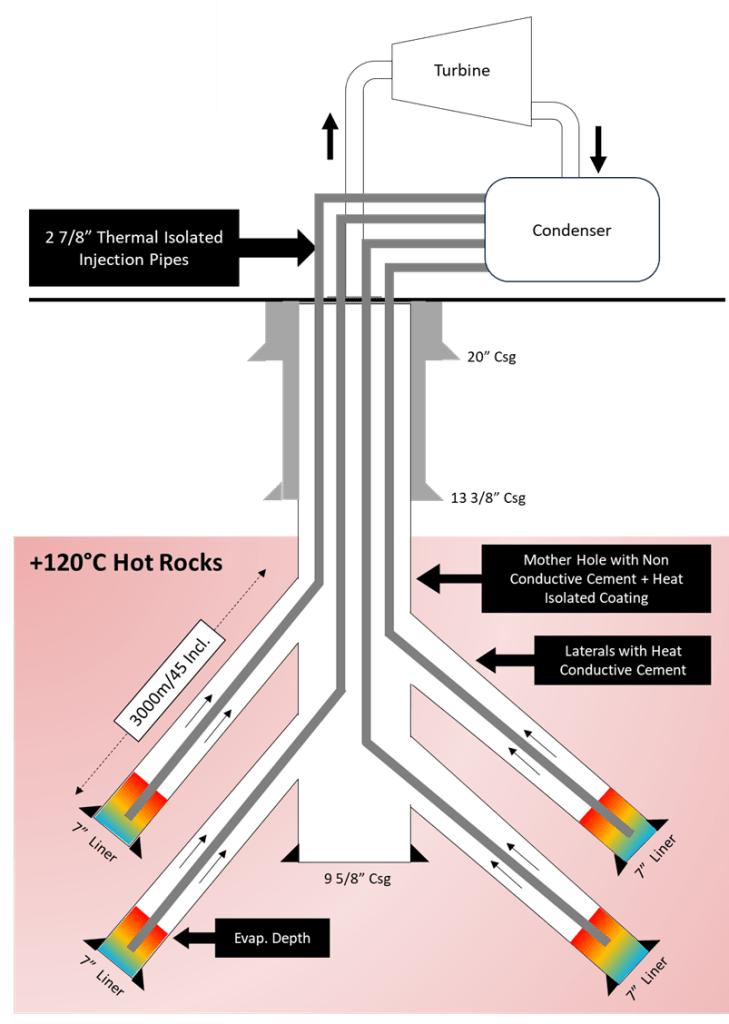

The integrated geothermal tree system (IGT) is a novel multilateral closed loop well design working as a giant Geo-radiator for optimizing geothermal energy extraction from any underground rocks with temperatures over 120°C regardless to rocks types or to rocks properties rather than all conventional geothermal technologies that targeting only the scarce water aquifers with high porosity and permeability.

Why IGT?

- Broad Global Deployment: With a deployment potential in over 80% of global regions at any geological setting regardless to rock types or their specific properties.

- Minimized Exploration/development Costs: The technology offers remarkably low exploration/development costs with virtually zero exploration/development uncertainty as it targets hot rocks above 120C heat without any specific rock type or rock properties.

- Scalable base-load electrical power generation system.

- Suitable for all geothermal resources from low to high-grade geothermal resources.

- Minimized Surface Footprint: as it a single-well design.

- Operating with zero harmful emissions without contaminations from aquifers.

- Exceptional Durability with Minimal Corrosion: The design ensures very low corrosion, leading to long-lasting performance and reliability with minimal risk of damage.

- Minimized Maintenance Cost with Rigless maintenance leading to reducing downtime.

IGT Working Principle

IGT is based on the integration of six effective elements to overcome the high cost and limitations of existing technologies: –

- Using long extended deviated/horizontal laterals to increase heat extraction surface area from the surrounding low-heat conductive rocks.

- Using a suitable low-boiling point refrigerant as a working fluid to extract and carry the geothermal energy to run the turbine which is more efficient than water.

- Simple multilateral well completion design for easy Rig-less installation and maintenance.

- Enhancing host rocks heat conductivity around laterals through injecting high heat-conductive cement to accelerate heat transfer toward the lateral

- Circulating the working fluids without using any electrical power (Injection by gravity and production by vapor pressure and thermo-siphon)

- Insulate the mother hole casing section by heat isolation paint to avoid heat loss.